Electroless Plating

Statement of the Problem

Plating and surface finishing processes often require the addition of chemicals (other than the object metal) into the plating or finishing solution. These additives are designed to improve the quality of the process or to impart a specific characteristic to the finished product. Unlike the concentration of an electro-deposited metal, which is generally self-regulating, additive concentration may require careful monitoring to avoid depletion.

Control Strategy

Automatic analysis of one or more control components of the bath can be performed at regular intervals with the information used to manually or automatically adjust the bath chemistry. A side stream sample is pumped to the process analyzer for analysis.

Apparatus

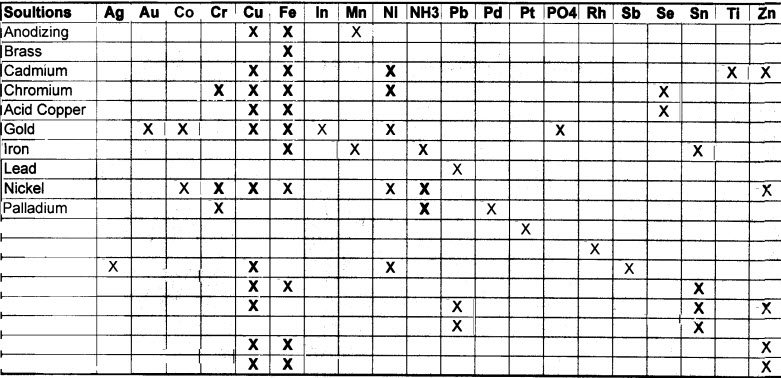

ChemScan uses multiple wavelengths for detection of specific metal ions while automatically compensating for the effects of turbidity and the presence of other chemicals. Reagents are used for some parameters that do not have natural UV-VIS absorbance spectra. Multivariate calibration techniques, including temperature variation effects are used to calculate the concentrations of one or more chemicals of interest. Many metal ions produce a specific color in water which is proportionate to the concentration of the ion. Other metal ions have natural light absorbance in the ultraviolet wavelength range or will produce colored compounds after the addition of a reagent (secondary analysis). The attached list of parameters are capable of analysis using ChemScan products

Plating and Surface Finishing Parameters